Error coins with clipped planchet

Coin blanks are punched out of long metal strips using a high-speed press. The strip is unwound from large rolls and fed through the press automatically. Several times per second the punches descend pushing out the blanks on the downstroke and leaving holes in the strip on the upstroke.

On each cycle the feeder mechanism pushes the strip far enough through the press that the punches descend onto clear metal. Occasionally, however, a misfeed can occur where the strip isn't fed through far enough. When that happens, the punches strike an area of the strip which overlaps the hole left by the previous strike. The result is a blank with a piece missing. If the blank makes it all the way through the coining process then the result is a coin with a "bite" out of it.

Note that in no sense is the blank, or the planchet it becomes after rimming,

"clipped". Nothing removed the metal; it was never there to begin with

so a more accurate description would be something like "incomplete planchet"

or "partial planchet". Nevertheless the term bitten or clipped planchet

is commonly used to describe this error.

Because the blanking punches are round, errors of this type typically show a curved segment missing from the planchet.

There are some characteristic features of coins struck on a partial blank which

help distinguish them from coins which have been mutilated after striking.

1. Rim beading absent or weak at the edge of the missing segment. This is caused

because the metal flows outwards rather than being forced up into the die by the

collar.

2. Blakesley effect (named for the American numismatist who first described it) occurs diametrically opposite the missing segment.

2. Blakesley effect (named for the American numismatist who first described it) occurs diametrically opposite the missing segment.

The so-called Blakesley effect occurs on most genuine error coins of this type and is characterized by a rim weakness directly opposite the main fault.

Coin blanks are put through a rimming machine before being struck. (The product of a rimming machine is a planchet.) The rimming machine comprises a concave curved wall and a roller set slightly off-centre so that the gap between the roller and the leading edge of the wall is slightly more than the diameter of a blank and the gap between the roller and the trailing edge of the wall is slightly smaller than the diameter of a blank. Blanks are fed in at the wider end, are progressively squeezed across their diameters as they roll around the curve and emerge from the narrower gap as planchets.

Now when a blank with a missing segment is fed into the rimming machine, all goes well until the missing segment comes into "contact" with the roller or wall. At that moment, the squeezing pressure drops to zero. Obviously no rim is formed on the inside curve of the fault, but also, no rim is formed on that portion of the blank opposite the fault.

Subsequently when the coin is struck, a rim may be formed by the action of the collar but it will generally be much weaker than normal. This is the Blakesely effect and is quite visible on the specimen shown here.

Another common feature of this type of error is extreme fishtailing. This specimen

does not exhibit that because the lettering near the fault is the wrong type for

showing that feature.

Straight Clip Error

The penny shown on this page is a good illustration of the clipped planchet error showing a straight clip. Clips are normally curved because the blank was punched from an area overlapping the hole left by a previous punching. Occasionally a blank will be punched from an area overlapping theendoredgeof the metal strip and the coin which emerges from this mishap will show a straight clip.

1963 Perth penny with a "straight clip" error

The specimen shown above illustrates the normal features of a genuine clipped planchet error. There is a strong "Blakesley Effect" on both sides of the coin in the area of the rim opposite to the clip. The clip itself is flanked by "shoulders" where the metal has not flowed up to the high points of the rim. These features are difficult for a forger to duplicate.

There are some numismatists who believe that straight clips only occur at the end of the metal strip. In considering this hypothesis it is important to remember that the ends of the metal strips are typically cut with mechanical shears as they leave the rolling mill.

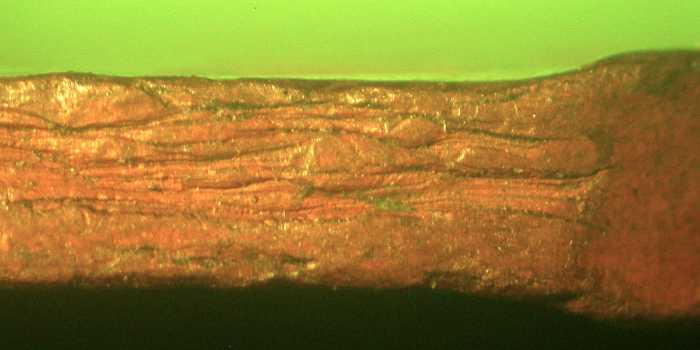

Edge view of the clipped area

The upper illustration above shows an edge-on view of the clip. Note the strongly layered texture which is the result of repeated compression of the metal strip in the rolling mill as it was reduced to the required thickness. That this is visible precludes any possibility of the clip region having been sheared or sawn in any post-milling operation. The blank for this coin was stamped from a region which was not subject to any such action and therefore not from the end of the strip. The only remaining explanation is that it was stamped from an area overlapping the edge.

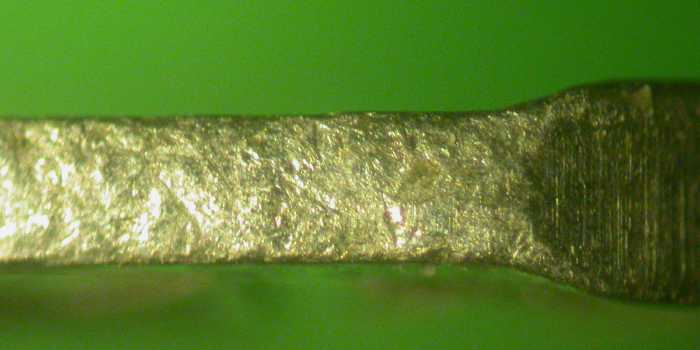

Note that it shows no hint of the layering visible in the upper image. Just to show that issues are not always clearly defined, a third edge-on view is shown below. This one is of a 1962 three pence straight clip error coin. Its clip region resembles that on the curved clip penny rather than the straight clip one. It is quite possible that this is an end clip but it is also possible that the repeatedly-compressed ingot of quad metal did not develop the layered texture of the bronze coin.

Edge view of a straight clip

on a three pence

Edge view of a straight clip

on a three pence

Other Australian coins errors

Mint error typesDouble die error

The 1916 mule halfpenny